Grease Boss G25 Model 216

The Grease Boss G25 216 was manufactured from late 2016 through to early 2020. It was produced with two electrical versions: V2.1a and V2.1b. The operation of each electrical version is identical, however the versions have slightly different servicing characteristics.

The G25 216 had the option of a pump-out unit installed (as shown). When installed the pump-out function was manually operated, but protected by an interlock to prevent the pump-out function from emptying the unit while the automatic heating cycle was active.

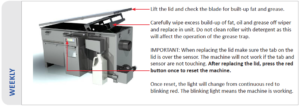

General Maintenance

The “Element??” fault is determined by measuring the temperature rise over a set period. The fault indicates that the system has tried to heat the tank but it did not heat within the pre-set 1 hour 30 minutes allowed.

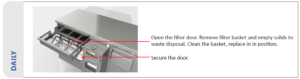

The pump out option on the Grease Boss 216 can be used to occasionally empty and flush out the unit, it may also reduce the frequency of external pump outs. You may want to do this to eliminate odour or sludge build up, however the usual daily maintenance on the grease trap is still required.