Oil & Grit Interceptors

Mactrap Oil & Grit Interceptors are used to protect water bodies and sewer systems from light fluids¹. Oil & grit interceptors seperate light oils and sediments collected in wastewater from sources such as petrol stations, car washes, vehicle repair garages and industry. Mactrap oil & grit interceptors are amongst the safest and most effective light fluid capture systems available.

Oil & Grit Interceptors can be used:

- For the treatment of rainwater contaminated with light fluids from surfaced areas.

- As a retaining system for light fluids where light fluids are handled.

- For the treatment of dirty water contaminated with light fluids.

- For the treatment of waste water produced by vehicle wash bays.

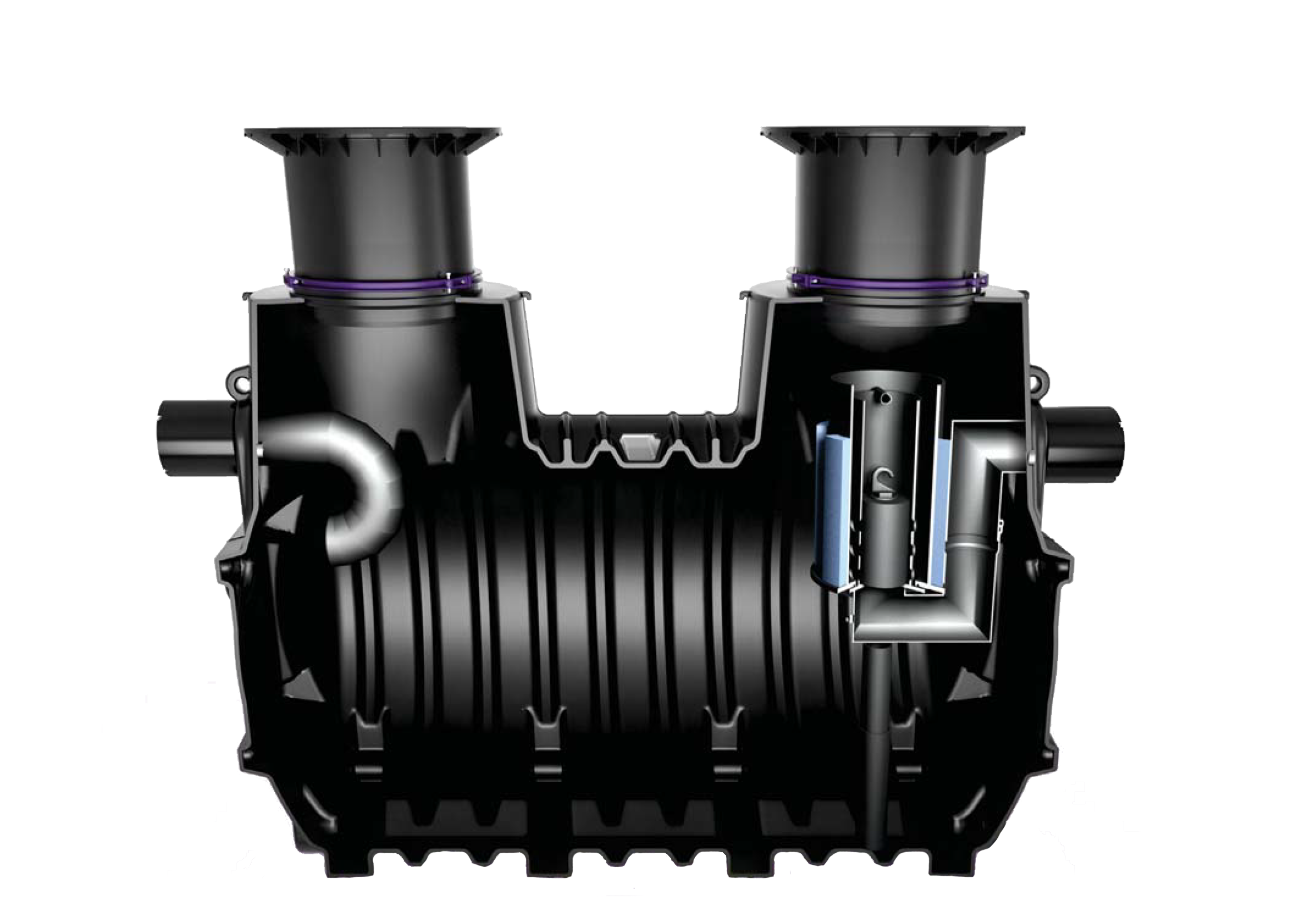

Coalescing Interceptor with auto shut-off valve

Oil & Grit Interceptors

Wastewater enters the interceptor and the heavier sludge and sediment sink to the bottom of the chamber while at the same time the light fluids rise to the surface. Cleaned wastewater exits the interceptor without allowing any of the separated sludge or light fluids to leave the separating chamber.

Coalescing Interceptors

Coalescing Interceptors operate on the same separation principle as oil & grit interceptors. A coalescence filter is integrated into the interceptor to catch droplets of oil too small to separate from the wastewater. Fine droplets of oil are trapped by the filter where they combine with other fine droplets until they reach buoyancy, and rise to the surface.

Automatic Shutt Off Valve

Both the oil & gritand the coalescing interceptors can be equipped with an automatic shut-off valve which completely closes the outlet of the interceptor when the interceptor reaches its maximum light fluid storage volume, or because of a large volume spill. This prevents the escape of light fluids into the drainage system.

Oil Level Measurement

To reduce the chances of the interceptor shutting down due to overcapacity in the oil storage chamber, an oil level measurement unit can be installed which monitors the oil level. Mactrap recommends the installation of these units in high spill risk applications. Oil & Grit Interceptors need only be emptied when they near capacity. The excessive cost of unnecessary scheduled emptying (or alternatively, shutting down because of full systems), can easily offset the oil level measurement installation.

Coalescence filter with auto shut-off valve

Features

Specifications

Model |

TREATMENT CAPACITY |

Oil Containment |

Length |

Width |

Height |

|---|---|---|---|---|---|

| MTFO250 | 253 l | 84 l | 1200 mm | 540 mm | 600 mm |

| MTFO500 | 507 l | 169 l | 1200 mm | 640 mm | 910 mm |

| MTFO750 | 758 l | 252 l | 1200 mm | 800 mm | 1060 mm |

| MTFO1000 | 1011 l | 337 l | 1600 mm | 800 mm | 1060 mm |

| MTFO1500 | 1517 l | 505 l | 2400 mm | 800 mm | 1060 mm |

| MTFO2000 | 2025 l | 675 l | 2800 mm | 800 mm | 1210 mm |

| MTFO2500 | 2528 l | 843 l | 2800 mm | 1020 mm | 1210 mm |

| MTFO3000 | 3027 l | 1009 l | 3000 mm | 1140 mm | 1210 mm |

| MTFO4000 | 4110 l | 1370 l | 3000 mm | 1160 mm | 1510 mm |

| MTFO5000 | 5100 l | 1700 l | 3000 mm | 1250 mm | 1610 mm |

| MTFO6000 | 6018 l | 2006 l | 3000 mm | 1475 mm | 1610 mm |

Data Sheets

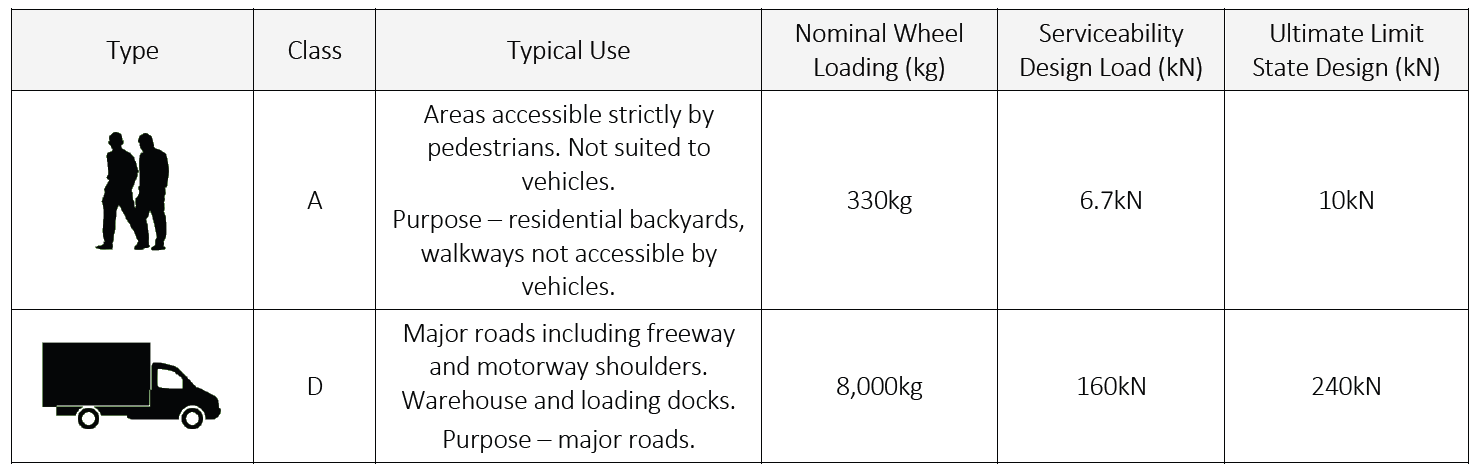

Covers & Risers

Mactrap separators are available with Class A Pedestrian lids in HDPE and Class D Vehicular lids in cast iron. The riser mounts are pre-welded and a flexible coupling allows easy installation of the fully sealed riser flanges and screw on covers. Surrounding concrete or other medium must be engineered for the appropriate loading.