Grease Traps for Separation of Fat, Oil and Grease

Grease traps separate fat, oil and grease from greasy water which typically results from the preparation and service of food. MACTRAP grease traps are Hydromechanical Grease Traps which means a design that incorporates air entrainment, hydromechanical separation, interior baffling, or barriers in combination or separately.

In the past concrete was commonly used in the manufacture of grease traps, but the presence of acids in greasy waste often resulted in corrosion and breakdown of the concrete material within as little as 10 years.

MACTRAP manufactures grease traps from High Density Polyethylene (HDPE) which remains totally unaffected by greasy water acidity allowing us to provide a 30 year warranty with all inground units – a strong financial motivation for building owners.

The benefits of MACTRAP grease traps start at installation. Because they are lightweight and easy to transport and maneuver they require less machinery and time to install saving up to 50% of upfront costs. If your application requires a custom size or configuration we can typically design and build to meet those requirements within two weeks.

MACTRAP manufactures products to support New Zealand’s environmental goals and all of our products comply with the NZBC G13.

Features

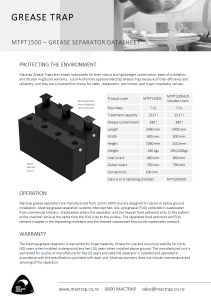

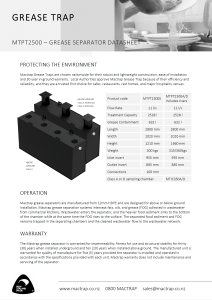

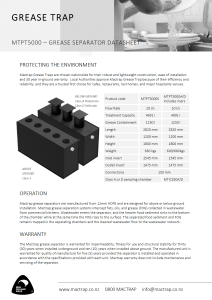

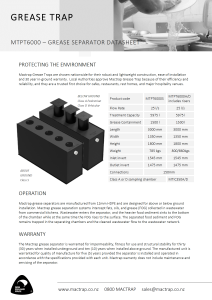

Specifications

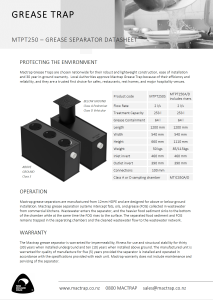

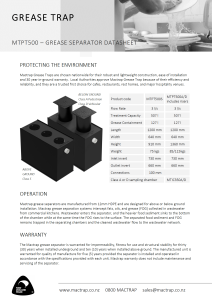

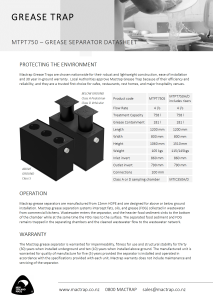

PRODUCT Code |

Treatment Capacity(litres)

|

Length(mm)

|

Width(mm)

|

Height(mm)

|

|---|---|---|---|---|

| MTPT250 (S) (A) (D) | 253 | 1200 | 540 | 660 |

| MTPT500 (S) (A) (D) | 507 | 1200 | 640 | 910 |

| MTPT750 (S) (A) (D) | 758 | 1200 | 800 | 1060 |

| MTPT1000 (S) (A) (D) | 1011 | 1600 | 800 | 1060 |

| MTPT1500 (S)* (A) (D) | 1517 | 2400 | 800 | 1060 |

| MTPT2000 (S)* (A) (D) | 2025 | 2600 | 880 | 1210 |

| MTPT2500 (S)* (A) (D) | 2528 | 2800 | 1020 | 1210 |

| MTPT3000 (S)* (A) (D) | 3027 | 3000 | 1140 | 1210 |

| MTPT4000 (S)* (A) (D) | 4110 | 3000 | 1160 | 1510 |

| MTPT5000 (S)* (A) (D) | 5100 | 3000 | 1250 | 1610 |

| MTPT6000 (S)* (A) (D) | 6018 | 3000 | 1475 | 1610 |

* Above ground traps from 1500L to 6000L are shipped with metal cages to prevent heat distortion.

** If required, the cages can be constructed for seismic restraint. Contact Mactrap for more information.

DATA SHEETS

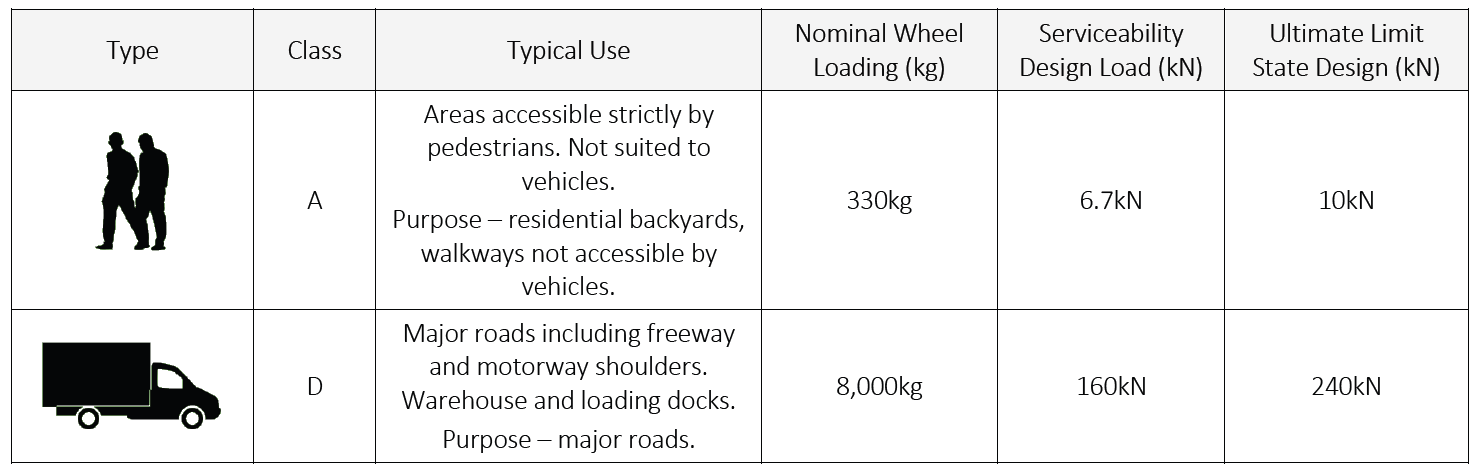

Covers and Risers

Mactrap grease traps are available with Class A Pedestrian lids in HDPE and Class D Vehicular lids in cast iron. The riser mounts are pre-welded and a flexible coupling allows easy installation of the fully sealed riser flanges and screw on covers. Surrounding concrete or other medium must be engineered for the appropriate loading.